Abs Plastic Sheet Forming Temperature

High density polyethylene hdpe which requires a core temperature of approximately 280 f for optimal forming.

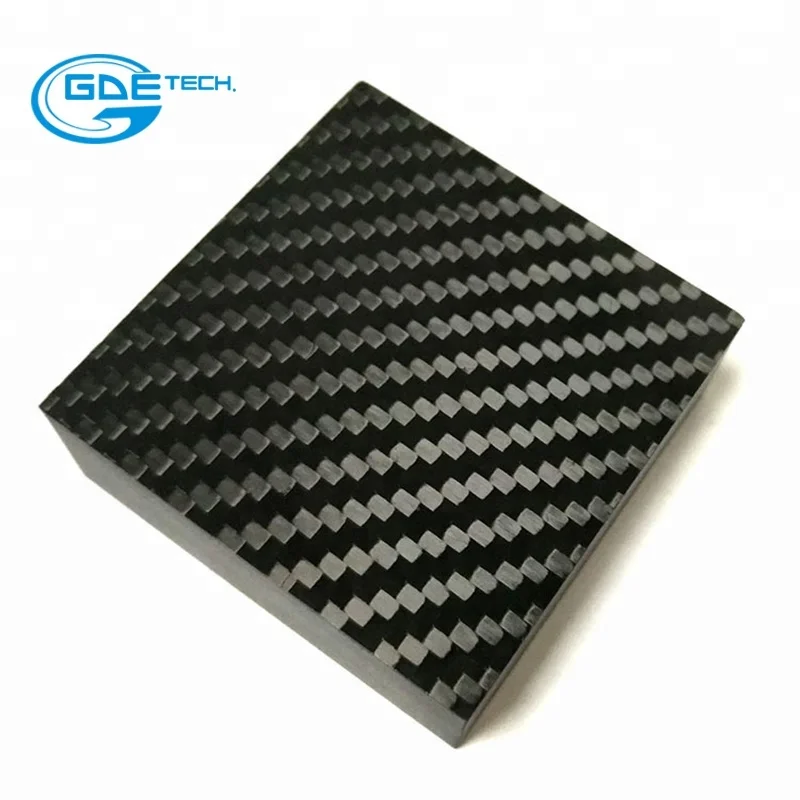

Abs plastic sheet forming temperature. It has very high impact strength and stiffness excellent high and low temperature performance and outstanding formability. Simply stated vacuum forming is the process of taking a flat sheet of plastic and changing it into a contoured shape. Acrylonitrile butadiene styrene abs chemical formula c 8 h 8 x c 4 h 6 y c 3 h 3 n z is a common thermoplastic polymer. Abs has desirable impact strength at room temperature and in special grades at temperatures as low as 40 f 40 c.

I have the oven set at 250f. Processing limit f c f c f c f c f c acrylonitrile butadiene styrene abs 185 85 260 127 280 138 300 310 149 154 360 182 acetate 160 71 260 127 280 138 310 154 360 182. I have a wooden form and a piece abs plastic that i laid on top of the form. To achieve this core temperature the former must calculate the temperature differential on both sheet surfaces.

Wait about 10 minutes for it to warm fully. Its glass transition temperature is approximately 105 c 221 f. This is accomplished by putting a piece of plastic into some type of clamping mechanism heating the sheet up to a forming temperature stretching the heated sheet of plastic over a mold sealing the heated plastic sheet on the. For example let s use 0 250 in.

Abs properties and material options. Royalite r20 thermoplastic sheet is a rigid abs product with a combination of properties that makes it ideal for the widest range of applications. Mold set lower orienting normal forming upper temperature processing limit temperature core temp. Abs works for some outdoor use.

Acrylonitrile butadiene styrene abs is an opaque thermoplastic and amorphous polymer. When it s ready you ll find it flexible when you try to pick it up. The spec sheet shows a temperature of 234 degrees. Have a glass transition at a certain temperature 221 degrees fahrenheit in the case of abs plastic.

Sheet surface temperature will directly correspond to material gage. In such cases a uv protective grade is better suited. Place the plastic sheet on a cookie sheet and place in an oven set to 250 f. Thermoforming sheets kits.

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature formed to a specific shape in a mold and tripped to create a usable product. This is my first attempt at oven forming abs plastic. Overexposure to the sun may cause color deformation and decrease the durability and overall appearance of the product. 7 put on your gloves when you work with the plastic.